- Book Cover

- Cabinetry

- Cardboard

- Containerboard

- Compressed Wood

- Copier Paper

- Currency

- Decorative Overlays

- Furniture

- Gypsum Board

- Inked Ribbon

- Inks

- Kraft Packaging

- Laminated Wood

- Newsprint

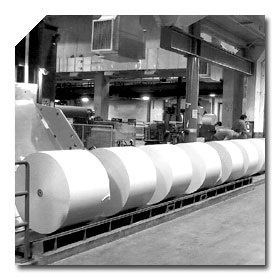

- Paper

- Paperboard

- Particleboard

- Printing

- Specialty Papers

- Tissue Products

- Wallboard

- Wallpaper

- Wood

- Writing Paper

- plus others

* The following suggestions are provided as a starting point for using the Taber Rotary Abraser to evaluate different materials. With the exception of the CS-5, the abrading wheels should be refaced prior to each test (based on the manufacturers recommendations) and a consistent vacuum nozzle height should be used (measured off the specimen surface). Other factors to consider include specimen conditioning, environmental conditions, vacuum suction level, specimen cleaning, and test cycles.

Paper and Cardboard � Abrasion Resistance

Specimen: 4 inches diameter or square with ¼ inch center hole for sufficiently rigid materials; for flexible materials, 4 inches round or square with ¼ inch center hole mounted on S-36 or S-36-1 Mounting Card

Wheels and Load: CS-10 Calibrase with 250 gram or 500 gram load

Evaluation: Visual changes (i.e. loss of luster; changes of surface; etc.); weight loss method

Remark: Duration of the test is a predetermined number of cycles (i.e. 100, 300, 500 or whatever number is needed to reach the degree of wear to be regarded as the end point of the test). The loss in milligrams is calculated on a 1000 cycle basis which gives a Taber numerical wear index directly comparable with that of similar materials tested under the same conditions.

Paper � Erasure Tests

Specimen: 4 inches diameter or square with ¼ inch center hole, mounted on S-36 or S-36-1 Mounting Card

Wheels and Load: CS-10 Calibrase with 250 gram or 500 gram load.

Evaluation: Visual end point determined by partial erasure of ink marks from wear path surface

Remarks: The properties to be determined are: 1) ease of erasure, 2) amount of damage to surface from abrasion, 3) ability of specimen to accept rewriting after erasure, 4) number of times the specimen will accept erasure and rewriting. The specimen is prepared by writing or drawing circular lines on the surface to be tested using a permanent ink. The ink should be thoroughly dried on the conditioned paper before testing.

Paperboard � Scuffing Test

Specimen: 4 inch diameter or square

Wheels and Load: H-10, H-18 or H-22 Calibrade with 500 or 1000 gram load.

Evaluation: Visual end point determined by comparison of the degree of scuffing with that of a standard sample tested under identical conditions

Alternate Wheels and Load: CS-5 with 250 or 500 gram load.

Evaluation: Visual change in gloss

Labels

Specimen: Affix to glass or metal specimen plates

Wheels and Load: CS-10 Calibrase with 250 gram or 500 gram load

Evaluation: Visual changes (i.e. loss of luster; changes of surface; etc.); weight loss method

Remark: Duration of the test is a predetermined number of cycles (i.e. 300, 500 or whatever number is needed to reach the degree of wear to be regarded as the end point of the test). The loss in milligrams is calculated on a 1000 cycle basis which gives a Taber numerical wear index directly comparable with that of similar materials tested under the same conditions.

Wood

Specimen: 4 inches square with ¼ inch center hole for materials to ¼ inch thick, 3/8 inch center hole for materials ¼ to ½ inch thick

Wheels and Load: H-18 or H-22 Calibrade with 500 gram or 1000 gram load

Evaluation: Weight loss or depth of wear method

Remark: For specimens ¼ to ½ inch thick, use S-21 Extension Nut

General Notes

- To generate useful data, specimens must flat.

- To prevent wrinkling, flexible samples can be mounted to the S-36 or S-36-1 Mounting Card.

- The effect of moisture on the wear factor of wood, such as decking, can be determined by soaking the wood in water for a specified length of time and testing in that condition, using the rimmed specimen holder (E140-75). To subject specimens to a wet abrasion test, the Textile Holder, Tensioning Type for Wet or Dry Testing (E140-18) can be used. This holder is designed to give an initial stretch to woven fabrics so that they may be tested while moist with minimum tendency to wrinkle.

Reference |

Title |

Scope |

| AS/NZS 4266.20 |

Reconstituted wood-based panels � Methods of test � Resistance to surface abrasion (Taber abrasion test) |

This standard specifies a method for determining the resistance to surface abrasion of decorative surfaces by using the Taber abrader. It is applicable to all low pressure overlaid particleboards and medium density fibreboards (MDF's). |

| ASTM G195 |

Standard Guide for Conducting Wear Tests Using a Rotary Platform, Double-Head Abraser

|

This guide covers and is intended to assist in establishing procedures for conducting wear tests of rigid or flexible materials utilizing the rotary platform, double-head abraser (RPDH). |

| ASTM F1478 |

Standard Test Method for Determination of Abrasion Resistance of Images Produced from Copiers and Printers (Taber Method) |

This test method describes a procedure for determining the amount of image abraded from the surface of a document. This test method may be used to evaluate the abrasion resistance of images produced by business imaging products, including non-impact printers, thermal transfer printers, and copiers. |

| DIN 53 109 |

Testing of Paper and Board; Determination of Abrasion by the Abrasion Wheel Method |

|

| DIN 68 861 T2 |

Furniture Surfaces: Behavior at Abrasion |

|

| EN 14323 |

Wood-based panels - Melamine faced boards for interior uses - Test methods |

This European Standard specifies test methods for the determination of characteristics of melamine faced boards (MFB) as defined in EN 14322. Section 5.9: This test measures the ability of the decorative surface of melamine surfaces board to resist abrasive wear-through by rotating a specimen in contact with cylindrical wheels covered with abrasive paper. The number of revolutions of the specimen required to cause a defined degree of abrasion is used as a measure of resistance to abrasion. |

| EN 14354 |

Wood-based panels - Wood veneer floor covering

|

Annex D - Test method for the determination of the resistance to abrasion; This Annex establishes a method of test for the determination of abrasion resistance of wood coatings and varnishes. |

| EN 13696 |

Wood and Parquet Flooring - Determination of Elasticity and Resistance to Wear |

|

| Ford Laboratory Test Method BN 108-02 |

Resistance to Abrasion - Taber Abraser |

This procedure is used to test the abrasion resistance of textile fabrics, coated fabrics, genuine leather, cardboard, rubber floor mats, carpets, other floor covering materials, plastics and painted substrates. |

| NASTA |

Manufacturing Standards and Specifications for Textbooks |

If offset printed on coated cover material, a protective top coating for abrasion resistance is required. |

| PR Env 175.333.08 |

Wood Flooring (including parquet) [and wood paneling and cladding] - Test Method to Determine Elasticity and Resistance to Wear |

This standard specifies two test methods to determine the resistance to wear of lacquered wood floorings. |

| SAE J 1847 |

Abrasion Resistance Testing - Vehicle Exterior Graphics and Pin Striping |

This SAE Recommended practice applies to the abrasion resistance testing of decorative tapes, graphics, and pin striping. It may also have relevance to certain vehicle labels and plastic wood grain film. The resistance to abrasive damage is judged qualitatively by its effect on the legibility, pattern, and color of the graphic marking. |

| SAE J 365 |

Method of Testing Resistance to Scuffing of Trim Materials |

This test can be used to determine the resistance to scuffing of test specimens such as fiberboards, fabrics, vinyl coated fabrics, leathers, and similar trim materials. |

| Tappi T 476 om-01 |

Abrasion Loss of Paper and Paperboard (Taber-type method) |

The objective of this method is to determine the resistance of surfaces of paper and paperboard to the action of abrasion, either wet or dry, by measuring abrasion loss. This test is not applicable to the surfaces treated with wax or similar materials which would fill in the pores of the abrasive wheels. |

| UNE 56-842 |

Kitchen Furniture. Tests for surfacing materials. |

This norm establishes the tests for surface coatings of kitchen furniture. |

| UNE 56-843 |

Kitchen Furniture. Physical tests. |

|

| UNE 56-868 |

Bathroom Furniture. Physical test methods. |

|

| UNE 57095 |

Paper and cardboard - Determination of Resistance to Abrasion - Taber Method |

This norm intends to describe to the method of measurement of the sensitivity of the faces of paper or cardboard to the action of standardized surfaces abrasives, as much in humid as in dry, using the Taber apparatus. |

| UNI 9115 |

Furniture. Test for surfaces finishes. Behavior of surfaces to wear abrasion. |

It establishes a method in order to estimate the surface of furniture and is used to maintain the design, color or aspect and subject them to abrasive action. The method is adapted in order to compare various finish systems, or as a control test in order to assure that a determined level of furniture surface performance is maintained and applied to all. It is not applicable to surface of leather, woven, natural and synthetic. Materials; equipment; reagents. |

|